- CI Factory project won award at the German Supply Chain Conference 2020

- TGW FlashPick® results in five times greater despatch capacity

- All processes are comprehensively cross-linked and digitalized

- High-performance combination of automatic mini-load warehouse and shuttle with one million storage locations and high-capacity commissioning for split cases and large-volume orders

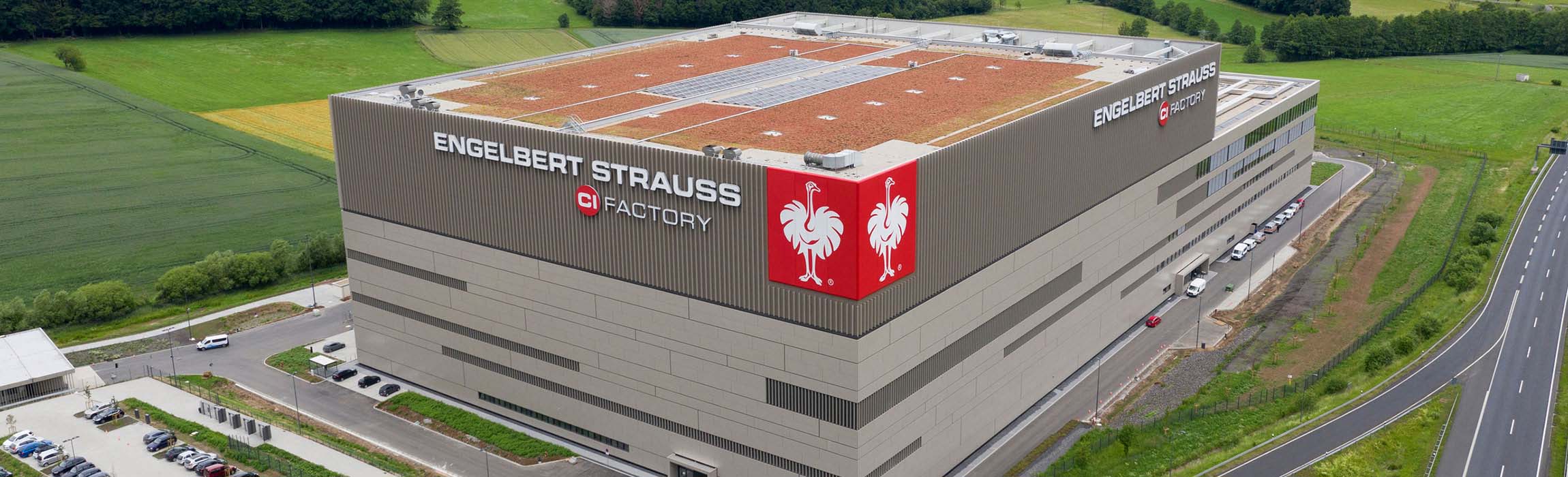

(Marchtrenk, Austria, 21 October 2020) Over the last few months, TGW constructed a highly automated omni-channel logistics hub for the leading manufacturer of workwear. In the CI Factory in Schlüchtern, Germany, production and logistics are intelligently cross-linked and fully digitalized. The entire plant was mapped using a digital twin. By using a TGW FlashPick® system consisting of a shuttle system and high-performance commissioning workstations, Engelbert Strauss meets the requirements for next-day delivery and has laid the cornerstone for new global growth.

Together with its partner, TGW Logistics Group, Engelbert Strauss won a prize at the German Award for Supply Chain Management 2020. The two companies were recognized for the project "CI Factory – Networking and digitalization in logistics and production". The certificate was handed out as part of the German Award for Supply Chain Management 2020 by the Bundesvereinigung Logistik (BVL) in Berlin on 21 October.

A family-owned company founded in 1946, Engelbert Strauss is one of the worldwide leading workwear manufacturers. The collections with the highly recognizable ostrich logo (Strauss = "ostrich" in German) are designed for business use and mostly delivered to customers from the skilled trades, industry and service. A feature that is unmatched worldwide: Companies can even have their shoes, jackets and trousers customized at the CI Factory, which turns employees into brand ambassadors. A special highlight is the shoe factory made of glass, which produces up to 400,000 pairs of shoes every year that are customized according to corporate design specifications from the customers – at series production costs. All in all, Engelbert Strauss invested over 200 million euros into the CI Factory lighthouse project.

Digital Twin

For the first time ever, a digital twin was used for a project of this type and scope. And it was used in every part of the project – planning, design engineering and real-time operations. The digital twin is a complete virtual representation of the CI Factory that allows all processes to be monitored and optimized. The digital twin is also a key component in the further long-term evolution of the CI Factory. It will optimize the operation of the plant for the entire life cycle of the project.

Omni channel logistics hub

The CI Factory covers an area of 94,000 m² and started operations in August 2020. A high-performance, future-proof FlashPick® system in what is dubbed the "logistics tower" is used for both the production logistics of the "Glass Shoe Factory" as well as order picking for deliveries made to online customers and stores.

"For us, TGW was one of the factors in the CI Factory project that ensured the project's success – you could even call them one of the key players in the entire project", emphasizes Matthias Fischer, Head of Operational Projects at Engelbert Strauss.

Up to 50,000 packages per day

The TGW solution consists of an automatic mini-load warehouse and a shuttle system with a million storage locations combined. The project also includes more than 13 kilometres of energy-efficient KingDrive® conveyor system and 28 ergonomic PickCenter One picking workstations, which function according to the goods-to-person principle. Thus, up to 50,000 packages per day can leave the fulfilment center on their way to the customers.

Moreover, the concept is already prepared for fully automated picking by the self-learning Rovolution picking robot, which will be implemented in the second stage. "Once more, TGW has been able to prove its expertise as a systems integrator," emphasises Johann Steinkellner, CEO Central Europe at TGW. "We couldn't be more pleased to have handed the system over on schedule. This demonstrates that TGW is a reliable partner for its customers."

Full-service package

During live operation, Engelbert Strauss will be able to rely on TGW's expertise. As part of a full-service package, on-site specialists provide support for the system together with the customer's technicians for a ten-year period.

Discover all details about the project