Optimum performance for MANGO

Project Motivation

Near Barcelona, a highly automated global multi-channel distribution center was created for the Spanish fashion retailer Mango. It centralizes all their fulfillment operations into one location. Currently, this central logistics hub is being used to supply more than 2,200 stores in over 100 countries. The highly automated solution ensures optimum performance and high throughput capacity.

Key Benefits

-

ENABLER OF BUSINESS GROWTH Thanks to the system's scalability, Mango is equipped for its growth plans

-

REDUCED INVENTORY AND FULFILLMENT COSTS

-

CONSOLIDATION OF TWO DCs INTO ONE Supply of more than 2,200 stores in over 100 countries from one DC

-

SIMPLIFIED PROCESSES FROM GOODS RECEIPT TO GOODS ISSUE

SOLUTION & MATERIAL FLOW

One-Touch Receiving

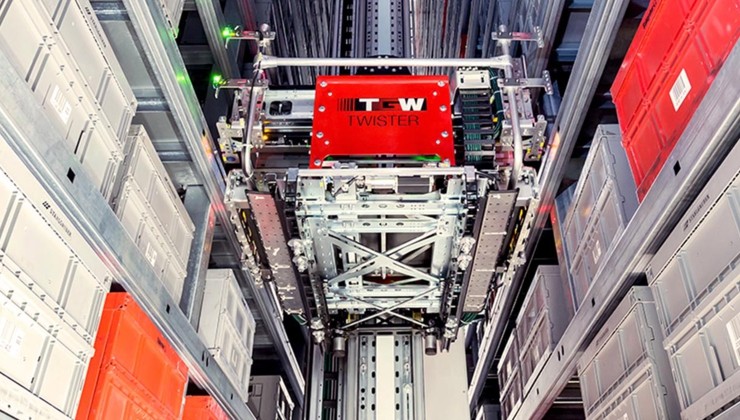

Mango handles up to 6,000 cartons per hour in their goods receipt area. Cartons are directly loaded onto extended conveyors from the trucks and automatically stored in a mini-load warehouse. In total, the automatic double stacked mini-load system provides 850,000 storage locations for cartons in different sizes. High-performance cranes store and retrieve up to 6,500 cartons per hour.

Order Fulfillment

Items retrieved from the mini-load system are first repackaged into totes at toting stations before they are stored in the shuttle system. The shuttle warehouse serves as a highly dynamic buffer for order fulfillment via picking workstations or sorters, depending on the order type:

- Cross-belt sorters are used to process most of the orders. Starting at 25,000 items per hour with low picking ratios and up to 30,000 items per hour with higher ratios. These are loaded onto the cross-belt sorter at the ergonomic infeed stations. The sorters transport individual items to chutes, where they are offloaded according to pre-cubing algorithms. At the end of the chutes, items are packed in order cartons.

- Prioritized orders, non-sortable items and slow-moving items are processed at high-performance picking workstations (goods-to-person workstations)

Order consolidation & shipping

All orders coming either from the sorters or the goods-to-person workstations are consolidated in the automatic mini-load warehouse and from there are transported to the shipping area. A linear sorter routes the order cartons to the dedicated lanes, where 5,800 cartons per hour are loaded into trucks.

HIGHLIGHTS

One-Touch Receiving

The smart inbound and storage system "One-Touch Receiving" allows Mango to automate its entire goods receipt process. The goods receipt lines use a cross-belt sorter to transfer up to 6,000 cartons per hour automatically to quality inspection (if required) and to the automatic mini-load warehouse for storage.

Multi-function carton warehouse

A special highlight of the overall solution is the enormous automatic push/pull carton warehouse on two levels with 850,000 storage locations. This makes maximum use of space of the warehouse's footprint. It is used for inventory storage, order consolidation as well as a dispatch buffer for flat and hanging goods (packed as flats in cartons prior to shipping).

ABOUT MANGO

Mango was founded in 1984 and has its headquarters in Lliça d’Amunt (Barcelona). Today, they are one of the world's leading fashion chains. The company is selling apparel, shoes, bags and accessories both online and in over 2,200 brick-and-mortar stores. The Spanish company is represented in over 100 countries.

The growth over the past years made it necessary to consolidate the supply chain. In order to optimize delivery times and reduce fulfillment costs, Mango opted for a central distribution center in the Catalan municipality of Lliça d’Amunt. Thanks to the system's scalability, Mango is equipped for its growth plans and has the necessary flexibility to adjust to changes in the order structure or its business model.

CURIOUS?

Raffaele Destro, Valentina Vivarelli, Berta Giramé

TGW Global Strategic Business Development Fashion

Message