- Leading sporting goods retailer boosts performance and efficiency of its fulfillment operations

- FlashPick® system accelerates shipments and provides the basis for future growth

- TGW Warehouse Management System plans, controls, and monitors all processes

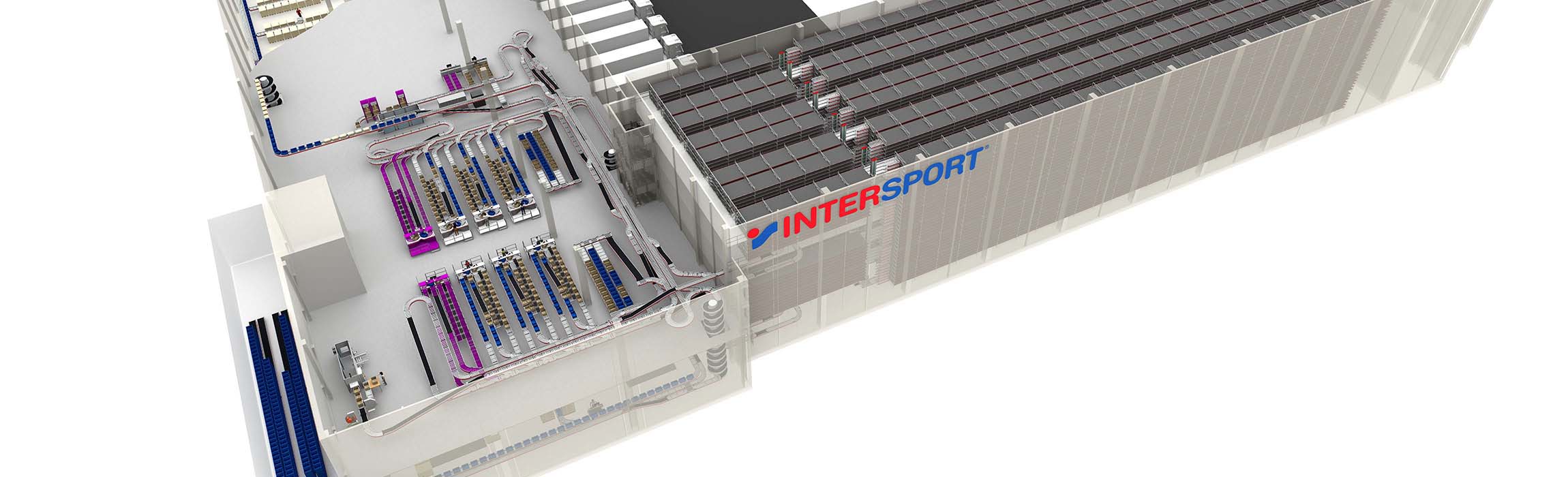

(Marchtrenk, February 9, 2023) With completion targeted for October 2024, TGW is setting up a powerful FlashPick® system for INTERSPORT Austria. The sporting goods retailer is consolidating multiple smaller distribution centers locations into its Austrian headquarters in Wels. Automation is the key lever for boosting performance and capacity and ensuring fast, dependable delivery.

The Wels-based INTERSPORT Austria Group is the country's market leader and includes 104 retailers at over 280 locations. In the 2021/22 fiscal year, the company generated a revenue of 631 million Euros. INTERSPORT Austria provides support to over 1.8 million customers and is responsible for the Austrian market as well as those in the neighboring countries of the Czech Republic, Slovakia, and Hungary.

"Wels is the hub where it all comes together, and logistics requirements are increasing. Expanding and automating this area was the next logical step. TGW provides everything from a single source, including everything from hardware and software to commissioning and user training. The total package is the right fit, and that's why TGW was awarded the contract," says Alois Grüblinger, Director of Operations INTERSPORT Austria.

Start of the joint journey towards automation

In order to reflect the company's growth in customers and orders and to ensure fast deliveries, INTERSPORT Austria is expanding its existing distribution center. Automation is intended to enable not only a significant boost in performance, capacity, and flexibility, but also to merge multiple small warehouses efficiently at one location.

TGW is setting up a four-aisle shuttle system which features triple-deep storage that ensures maximum storage density and makes optimum use of the available space. Orders are sequenced and picked at six PickCenter One picking workstations, while shipping cartons are automatically erected and fitted with lids by TGW robotics before being transported to the outbound area. TGW's Warehouse Management System (WMS) plans, controls, and monitors all processes and is connected to INTERSPORT's ERP system.

"During the sales design phase, TGW provided both professional collaboration of the various teams and many innovative suggestions for optimizing our current logistics processes. Therefore, we're confident that in TGW, we have the right partner on board," says Günther Junkowitsch, Head of Logistics at INTERSPORT Austria, who is responsible for the entire project.

Software expertise is the crucial factor

"We couldn't be more pleased that INTERSPORT Austria trusts TGW's warehouse automation expertise and experience," says Johann Steinkellner, CEO TGW Central Europe. "The decisive criterion in the project is our software expertise. The TGW WMS will replace INTERSPORT's existing system, in the automatic as well as the manual system areas."