- Temperature-controlled warehouse ensures optimal product quality along the supply chain

- Fully or partially automated compilation of orders onto shop-specific roll cages

- Increased operational efficiency

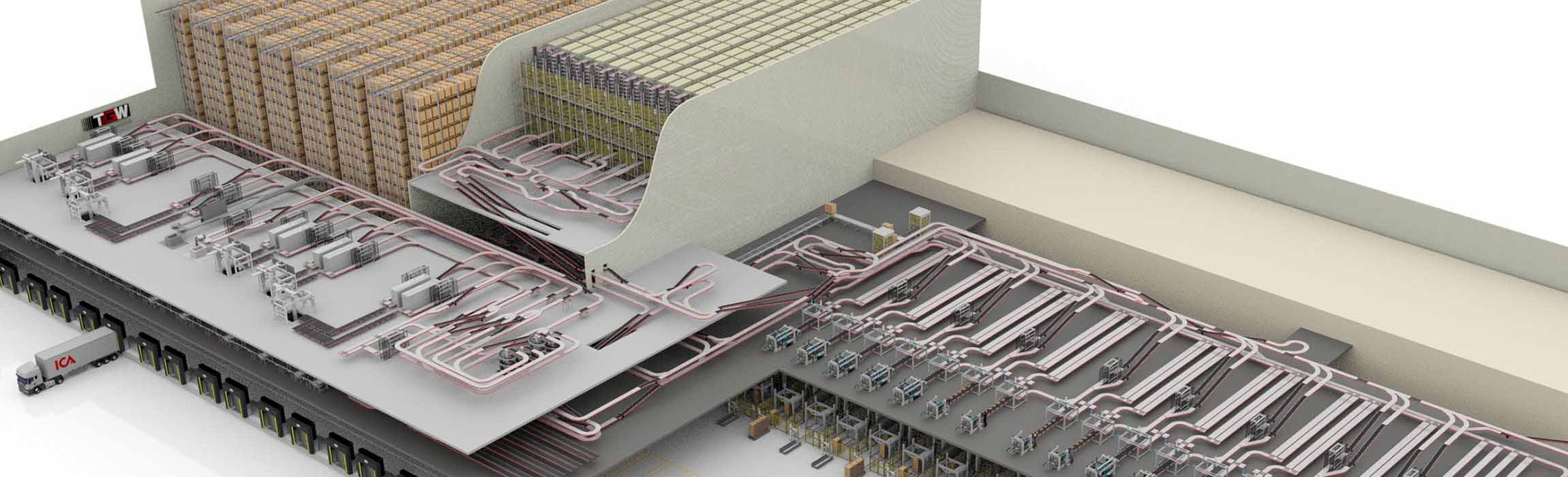

(Marchtrenk, 8 September 2022) About sixty miles west of Stockholm, TGW is working on a flagship project for Sweden’s number one grocery retailer, ICA Sweden, and is scheduled to finish by January 2026. This highly automated fulfillment center will allow ICA Sweden to increase the efficiency of its processes and expedite delivery to its shops.

An approximately nine-story-high freezer warehouse for pallets will replenish a highly dynamic shuttle system that will allow direct access to each and every item and facilitate the shortest possible lead times. For each shop order, the required items will be retrieved, sequenced, and then picked. Orders are then stacked onto the appropriate roll cages for each shop at either fully or partially automated workstations. Interconnecting each of the functional areas of the fulfillment center are energy-efficient pallet, carton, and tote conveyors.

Efficient shop replenishment

TGW Warehouse Software will ensure optimal item arrangement on each roll cage, minimizing the time and effort spent restocking store shelves. Compared to manual order picking, the compact arrangement of the automation system will also mean a significant reduction of the volume of space that needs to be kept cool, which will support ICA in achieving its sustainability goals.

In the frozen temperature zone of the fulfillment center, all automation technology is designed for use at -13 °F. This includes the storage process, as well as picking and palletizing. ICA will join the list of dozens of companies, including Coop (Switzerland), NewCold, and Nordfrost, that have seen TGW’s proven success in productivity, efficiency, and reliability in chilled and frozen environments.

Common journey towards automation

"We are delighted to accompany ICA as a partner on the journey towards automation," affirms Kristian Brink, Sales Project Manager at TGW Scandinavia. "Together, we will tailor the warehouse automation to the needs of the Swedish market and implement a solution that sets new standards."