In today’s intralogistics, companies face a variety of challenges. From labor shortages to increasing demands for flexibility and the integration of automated systems into existing facilities, the requirements for efficiency, productivity, scalability, and flexibility are higher than ever. TGW Logistics addresses these challenges with a comprehensive portfolio that sets new standards, particularly through advanced solutions in the field of mobile robotics.

Flexible Scaling and Easy Expansion

In the rapidly changing business world, logistics facilities must be able to respond flexibly to new requirements. Whether due to increasing order volumes or the introduction of new business models, the need to scale and expand facilities is ever-present. Our mobile robotics solutions are designed precisely for this purpose. They can be quickly implemented through easy-to-use software and effortlessly grow with your company’s needs. From a single robot to a complex, harmoniously operating ensemble, our solutions offer the flexibility your company requires.

Adaptability to Dynamic Market Requirements

Seasonal peaks and changing market demands pose particular challenges to the flexibility and adaptability of logistics processes. Systems based on mobile robotics are designed to adapt to these dynamic requirements. The resulting advantages include seamless integration into various warehouse and production areas, as well as the continuous mapping of new tasks. This ability to flexibly respond to changing process requirements ensures that your facility always operates at peak performance.

Seamless Integration into Existing Systems

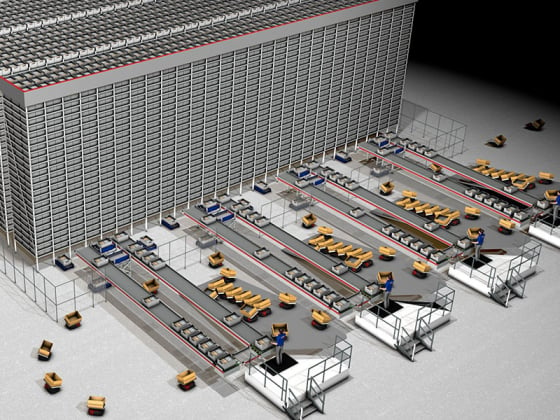

Implementing automated systems in existing facilities, especially during ongoing production, is often a complex challenge. Our mobile robotics solutions significantly simplify this process through a high degree of pre-prepared in-house activities and minimal necessary adjustments to existing infrastructure. Our robots ensure high availability and stability, so your performance is not disrupted during integration. This allows for smooth expansion or retrofitting of your facility without costly downtime.

Harmonious Collaboration Between Humans and Machines

In many companies, manual and automated processes must coexist efficiently. Our mobile robots are designed to work in challenging or dynamic environments, reducing risks for human workers. This harmonious collaboration between humans and machines increases workplace safety while simultaneously improving overall productivity.

Optimized Fleet Management with WERX Mobile Robotics

A key component of our mobile robotics solutions is the fleet management software from WERX. WERX Mobile Robotics monitors and coordinates the operation of all mobile robots in a warehouse. As the central control element of the robot fleet, the WERX software optimizes task distribution, route planning, and traffic management. It enables seamless integration with other warehouse management systems, ensuring maximum productivity and efficiency.

WERX Mobile Robotics is robust and flexible, making it optimized for use in various industries. It offers advanced features such as predictive maintenance planning and performance analysis. These features help maximize the reliability and efficiency of your entire logistics facility, making the software an indispensable tool in modern intralogistics. The intuitive and modern user interface is integrated into the WERX portal.

Conclusion: A Future-Proof Solution for Intralogistics

Companies face numerous challenges in modern intralogistics. TGW Logistics’ mobile robotics solutions provide a powerful and flexible response to these demands. With innovative technologies and the robust WERX software, we deliver the tools companies need to optimize their logistics processes and successfully meet the challenges of the future.