GAP automates case handling

Project Motivation

Since 1969, GAP has grown from a single retail store to the largest speciality fashion retailer in the US with seven major brands (Gap, Banana Republic, Old Navy, Athleta, Intermix, Hill City, Janie and Jack). GAP's main goal was to improve operational efficiency by reducing the number of manual touches in its DCs. They have invested in highly automated case handling technology over the past eight years at their fulfilment centres in Fishkill (US), Fresno (US), Gallatin (US), Groveport (US) and Brampton (CAN).

Key Benefits

-

REDUCE OPERATIONAL COSTS Eliminating manual touches prior to picking (One-Touch Receiving) helps reduce costs and improve process speed and quality.

-

LESS RELIANCE ON LABOUR The ability to find enough operating personnel for the fulfilment centres is the biggest issue. Implementing a solution for case handling that utilises a high degree of automation allows the goods receiving process to function efficiently without disruptions, even during peaks.

Initial Situation

GAP's distribution network is based on decentralised DCs (nine in the US, one in Canada) for retail and e-commerce orders in North America. In the past, processes were manual and the fashion retailer had a need for improved operational efficiency.

Its goods receiving and storage process showed a high potential for optimisation. Therefore, the company decided to invest in a highly automated solution that allowed it to eliminate seven touches from its manual process. The goods receiving area now only needs the operator to unload the product from the trailer before it is picked for customer orders. GAP was able to set a milestone in operational performance with this solution and has already upgraded seven of its DCs in North America.

Solution & MaterialFlow

- Goods receipt and storage

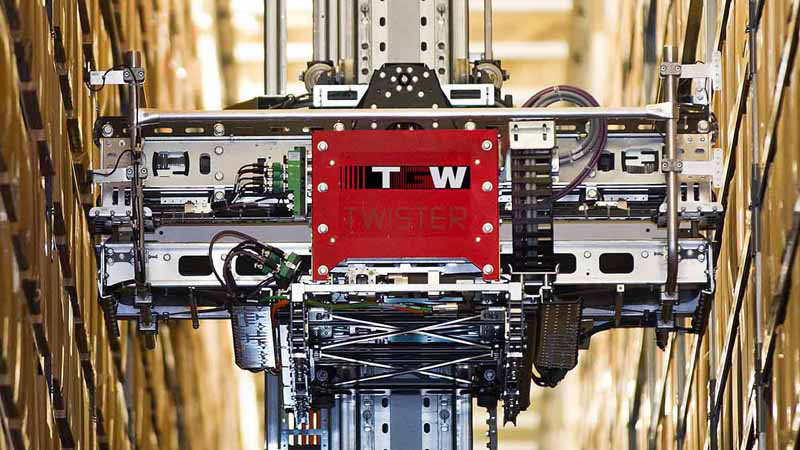

The standardised 'One-Touch Receiving' goods receiving and storage system is integral to the goods receiving process. Vendor cartons are unloaded from the trailer, sent through a quality check automatically and are then stored in a mini-load system based on high-performance storage and retrieval machines which are eleven metres tall. - Order fulfilment

The mini-load system supplies a unit sorter, which sorts the required items into the shipping cartons. Any source carton that still contains product is returned to a temporary storage buffer based on shuttles that handles these opened cartons. - Outbound area

The completed shipping cartons are conveyed to the correct dock door locations, where they are loaded onto trucks for delivery.

Highlight

One-Touch-Receiving - efficient goods receiving and storage system

By implementing 'One-Touch Receiving' for its goods receiving process, GAP was able to increase efficiency with an ROI of less than two years. GAP was able to eliminate seven of eight manual touches with this solution: The cartons are unloaded from the truck and directly placed on an extendable conveyor belt. Subsequently, the fully automatic process with quality inspection (weight, volume, carton outline) and the scan process begins. After being received in the system, the delivery quantity is compared to the order quantity, and after a conformity check, the goods are stored in a mini-load warehouse.

About GAP

Founded in 1969, GAP Inc. has grown to a global leading retailer offering apparel, accessories, and personal care products for men, women, and children. The GAP brands include Gap, Banana Republic, Old Navy, Athleta, Intermix, Hill City, and Janie and Jack. In 2019 the company generated revenues in excess of 16,383 million USD and employed over 129,000 people. Gap is present in 90 countries worldwide and operates over 3,345 company-operated stores, almost 574 franchise stores as well as e-commerce sites.

CURIOUS?

Raffaele Destro, Valentina Vivarelli, Berta Giramé

TGW Global Strategic Business Development Fashion

Message