- Automation of manual processes increases flexibility while reducing operating costs

- TGW Warehouse Software plans, controls and monitors all processes

- Robots handle putting together customer pallets and depalletising empty totes

(Marchtrenk, 4 April 2022) TGW is building a high-performance fulfillment center for UpFresh in the harbour city of Ostend, with completion scheduled for November 2023. Automation will allow maximum flexibility and help the Belgian grocery specialist meet its ambitious growth targets.

UpFresh is one of Belgium's leading grocery retailers, supplying over 2,700 shops with meat, cheese, salads and convenience products. Speed is central to the B2B specialist's business model. Customers can place orders seven days a week; those who place their orders before 6 p.m. can expect to receive their fresh goods the very next day.

TGW Warehouse Software manages all processes

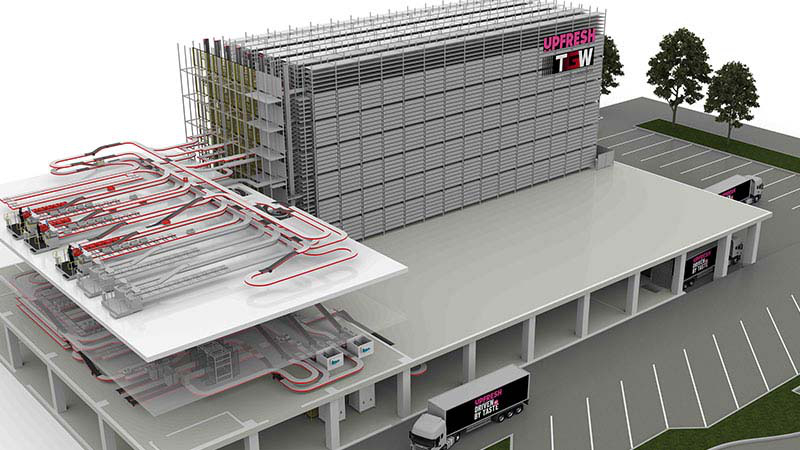

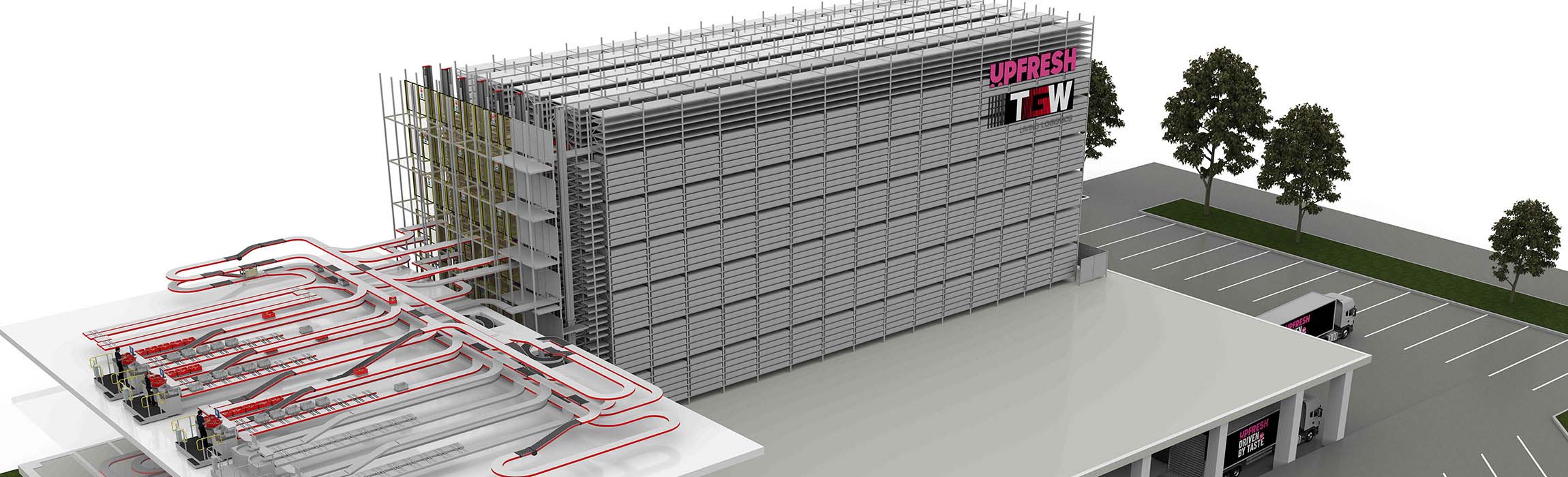

The core element of the system will be a three-aisle shuttle warehouse that will maintain a temperature of two to four degrees Celsius. This will serve not only for goods storage but also as a buffer for empty totes and order totes. Orders will be picked at three high-performance PickCenter One workstations.

Robots will handle the fully automated process of putting pallets together as well as depalletising empty totes. The individual areas of the fulfillment center will be connected by more than 1.5 kilometres of energy-efficient KingDrive® conveyors. All processes will be planned, controlled and monitored by the TGW Warehouse Software, which will act as Warehouse Control System (WCS) and Material Flow Controller MFC.

High-performance intralogistics as the foundation for planned growth

The new distribution centre will help UpFresh meet its growth targets and will constitute the foundation for quick, reliable service. The solution will allow maximum flexibility, thereby helping to sustainably reduce operating costs.

"We have been working closely with the customer to develop a solution tailored to UpFresh's needs," says Hans De Sutter, Managing Director at TGW Benelux. "The installation's layout is designed to be fit for the future: it can be quickly expanded to double the performance, if needed."